Under the Modern Slavery Act of 2018 [1] Australian businesses must report their exposure to modern slavery in their supply chains. However, discovering whether modern slavery exists in complex and global supply chains is difficult, even when businesses are well-motivated. Modern slavery can come in many forms. For example, debt bondage or bonded-labour, can trap workers in coercive situations until a debt is repaid. Workers may also be subjected to wage exploitation, where wages are severely underpaid [2]. Furthermore, the victims of human trafficking may be forced to work and have their passport or visa withheld.

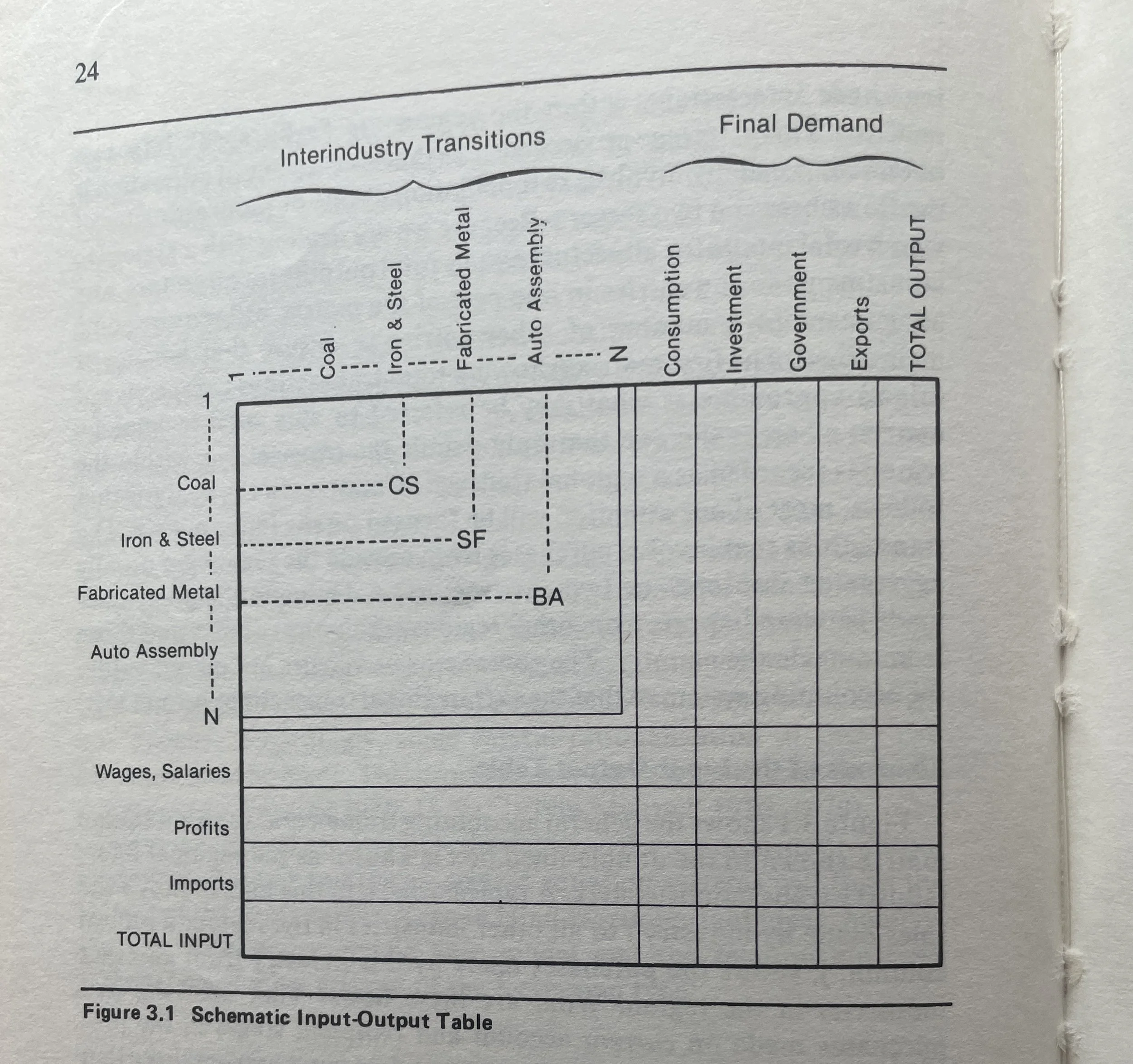

Recently, attempts have been made to trace modern slavery in supply chains using input-output analysis [3,4]. Input-output analysis (IOA) is a powerful technique for tracing impacts along supply chains and has been used to successfully calculate carbon footprints. However, these supply chain analyses may be somewhat fraught when used to trace modern slavery.

By its’ nature, modern slavery is illicit and occurs in the shadows. This means that modern slavery data is scant, incomplete and often published with high uncertainty. Modern slavery auditors can conduct factory inspections to check for slavery-like conditions, however it’s not clear how results from specific factories can be used to make generalisation about whole sectors or industries. Other datasets and indicators are potentially correlated with modern slavery, for example skill, income, access to education and employment opportunities, access to trade unions and freedom to associate. Unfortunately, using inequality as an indicator risks painting all nations with high inequality, often in the global south, as complicit in modern slavery.

One assumption of IOA theory is that the firms within a sector are generally similar or homogeneous with respect to their direct intensity qj. That is, the direct intensity qj of an individual firm is similar to the group of firms comprising the sector. For the case of GHG impacts, we expect firms within a sector to have roughly comparable qj values since emissions generation is strongly influenced by technology and thermodynamic limits.

However for impacts that are sparsely distributed among firms, such as modern slavery, this assumption of sector homogeneity breaks down. Most firms will contribute zero to the sector's total impact, with perhaps only several firms contributing non-zero intensities. The implication of this is that the majority of the sector's output is not associated with modern slavery and the majority of the firms in the sector are not responsible for it. This makes it difficult to interpret footprint results implicating this sector in modern slavery.

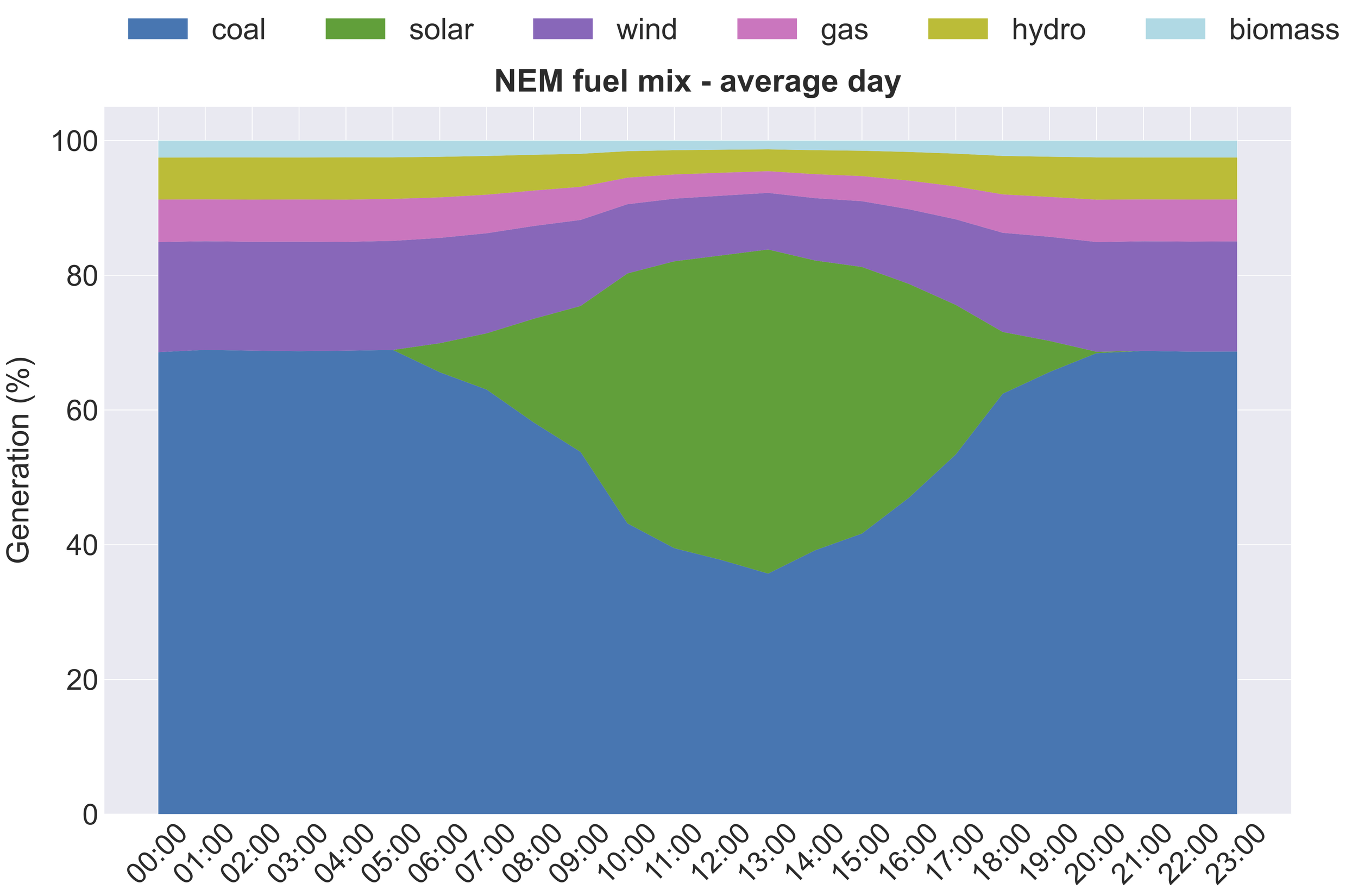

The issue of sector heterogeneity can also be seen in the light of aggregation error. Aggregation error occurs when dissimilar firms are aggregated into the same sector within an IO model. With more information we could disaggregate the 'sparse polluters' from the rest of the sector. In fact, statistical offices and IOT compilers will create new sectors when technology and production recipes vary greatly within existing sectors, for example splitting coal-fired and hydroelectric from all electricity generation. However there is not enough information to perform this disaggregation in the case of modern slavery.

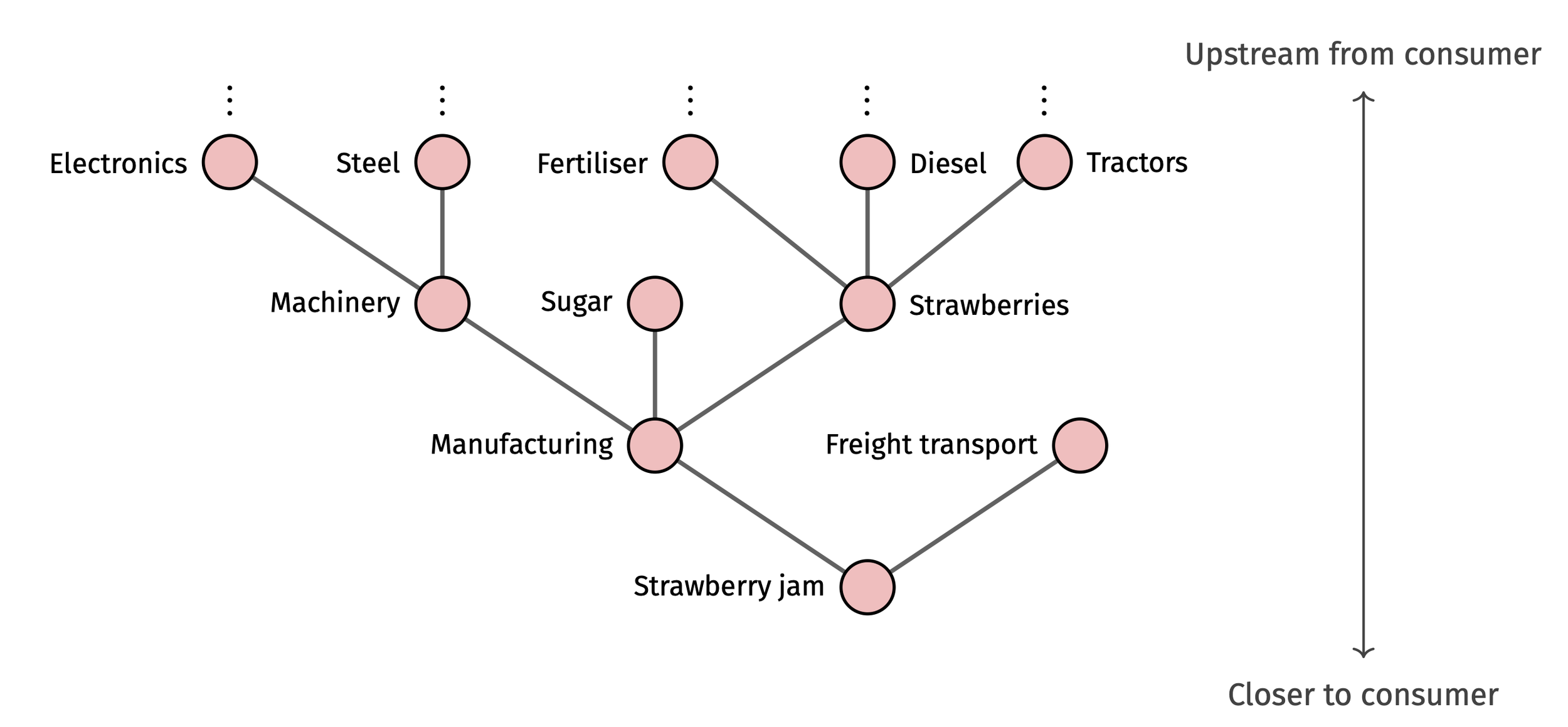

Despite these challenges, there are still tools available to improve supply chain transparency. For example, the freight and logistics industries have developed a number of technologies [5] to improve transparency in cold-chain logistics to prevent food wastage, reduce supply chain disruptions and to provide proof of cold-chain breaches. Unfortunately freight transport can also be a conduit for human trafficking and facilitate modern slavery. Transparency of container access can help mitigate this risk, as well as other issues such as product loss through pilfering. Another aspect to transparency is who reaps the rewards of our consumption. In some cases the lower order production layers, such as retailing, can gobble up a large fraction of total product cost and the workers at higher production layers remain lowly paid [6].

[1] Modern Slavery Act: https://www.legislation.gov.au/Details/C2018A00153

[2] https://www.governmentnews.com.au/migrants-trapped-in-slave-like-conditions-at-aussie-farms/

[3] Shilling et al., 2021, Modern slavery footprints in global supply chains, Journal of Industrial Ecology

[4] https://www.sydney.edu.au/science/our-research/research-areas/physics/big-data-combatting-modern-slavery.html

[5] Such as: https://opensc.org/, https://www.cargoai.co/, https://www.enkibox.com.au/

[6] https://theconversation.com/it-would-cost-you-20-cents-more-per-t-shirt-to-pay-an-indian-worker-a-living-wage-88309